- 10/29/2021

- 2 Min Read

- By: Andrew Peng

6 Tips For Effective Use Of Anti-Seize Compound

Anti-seize grease or compound is commonly applied to fasteners to prevent the threads from becoming galled or damaged, especially when dissimilar metals are involved. For people that live in locations where corrosion is a persistent issue, anti-seize is an invaluable tool to have, helping to prevent thread damage and contamination from corrosion.

You should know that improper use of anti-seize can do just as much damage, if not more than it is meant to prevent. The tips below cover how to use it properly and how not to use it to ensure your projects go smoothly.

Shop Chemicals & Fluids At FCP Euro

Use anti-seize sparingly

The goal of using anti-seize compound is to coat the threads with the compound preventing corrosion and adhesion between the thread and the fastener. Too much anti-seize applied to the thread can attract debris that may contaminate the thread and prevent the fastener from being removed cleanly.

There is no reason to use more anti-seize than absolutely necessary on the threads you are coating. Additional anti-seize does not offer any more corrosion protection and is simply a waste of product.

Too much anti-seize applied to the threads of a bolt.

Too much anti-seize applied to the threads of a bolt.

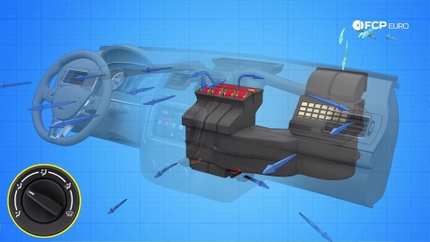

Reduce torque values by 25% to 30%

This is commonly forgotten and extremely important. Torque ratings on fasteners are based on their target clamping force. Anti-seize will act as a lubricant; those lubricating properties will significantly decrease the required torque to achieve the desired clamping force. This is often referred to as a torque multiplier. Using anti-seize without reducing the required torque value can strip the threads or stretch the bolt in extreme situations.

The exact value of torque reduction varies with material, and you should consult the manufacturer's specifications when in doubt.

Pay careful attention to torque specifications when using anti-seize

Pay careful attention to torque specifications when using anti-seize

Use the right type of anti-seize for the application

Most people are familiar with the ubiquitous silver tub of anti-seize made by Permatex, which is stable up to 1600F. We also sell a copper anti-seize made by LIQUI MOLY, called LM 508, which is stable up to 2012F. Depending on the application, another benefit of the copper anti-seize is its electrical conductivity.

Nickel-based compounds are available and are designed to be used when fasteners must be kept free of copper contamination. Even though the silver tub of anti-seize linked above isn't copper-based, it does still contain copper.

Copper anti-seize vs aluminum anti-seize

Copper anti-seize vs aluminum anti-seize

When not to use anti-seize

While anti-seize can seem like an excellent idea on some stubborn fasteners or a shortcut to a proper repair of damaged fasteners, you should not use anti-seize in some applications. If the thread is already damaged or cross-threaded, do not use anti-seize to help install the fastener. The threads need to be chased, re-tapped, or repaired. Do not use anti-seize as a lubricant such as on caliper slide pins or on threads for a bushing press or any mechanical assembly that requires a lubricant. Do not use anti-seize on exposed threads because the compound can attract contaminants that may contribute to thread damage when the fastener is removed.

Two of the most-asked about applications we get are, "should you use anti-seize on spark plugs" and "should you use anti-seize on lug nuts?" The answer to both of those is no! Neither application requires anti-seize, and in fact, in both, you run the risk of doing damage.

Anti-seize should not be applied to lug nuts

Anti-seize should not be applied to lug nuts

When to use anti-seize

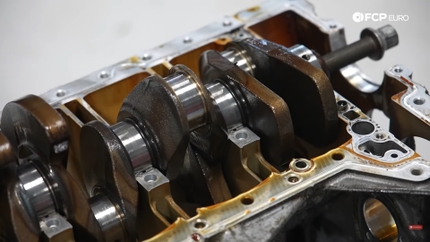

There are some definite scenarios that you should be using anti-seize. Anti-seize should be used when dissimilar metals are involved (steel bolt into an aluminum brake caliper), when threads may be exposed to corrosive effects (suspension fasteners), where high-heat may accelerate corrosion (manifold, turbo, and exhaust fasteners), and on fasteners that frequently get removed (underbody trays covering the oil pan).

In all of these scenarios, the anti-seize should only be used between the threads of the fastener and the nut or tapped housing it threads into. Using anti-seize on any exposed threads of the fastener runs the risk of contaminant buildup and damage upon removal.

Anti-seize providing corrosion protection

Anti-seize providing corrosion protection

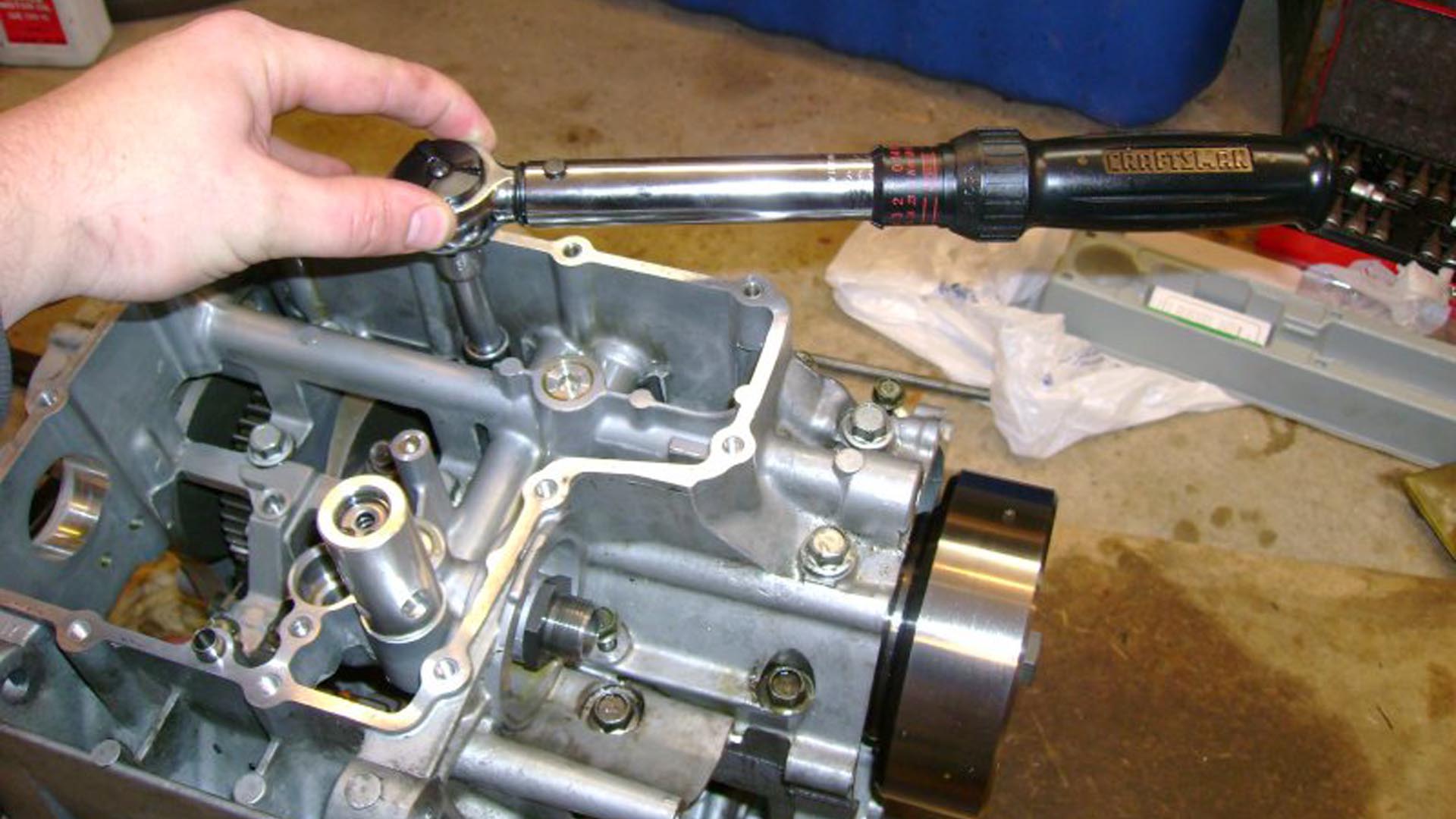

Clean excessive anti-seize after assembly

This might seem obvious and a bit redundant by this point, but when putting your component back together and installing the fasteners, wipe off excessive anti-seize that is exposed. As mentioned above, extra anti-seize will attract contaminants that may damage threads. The only part of the fastener that needs anti-seize is where the two materials meet, under the head of the fastener and in the threads. For through-hole applications, clean the exposed thread as well.

Correct amount of anti-seize applied

Correct amount of anti-seize applied

If you have any more tips/tricks on how to use anti-seize or lesser-known uses for the slippery substance, leave them in the comments section below.